Much of the country has been getting slammed by heat waves this past week. According to the Chicago Tribune we may see record breaking temperatures in Chicago today. The hot weather wreaks havoc on utilities, people, and products. In part one of this post I'm going to discuss how the hot weather can affect your goods and then make the case for monitoring them. In part two I'll provide an example and real temperature data as evidence as to why this is a serious issue.

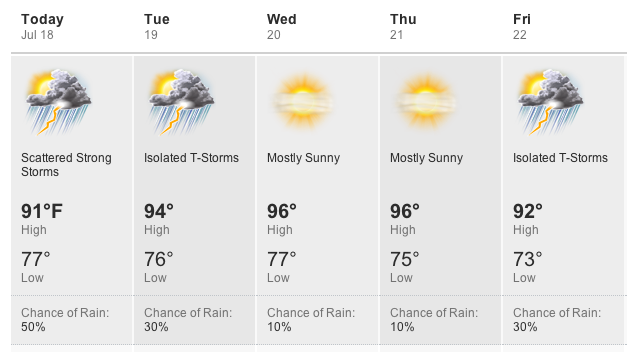

First, let me set the stage. Here's a screenshot I took this past Monday of the weather forecast for the week:

So, it's a hot one for Chicago (yeah, yeah - if you're in the Southwest I know it gets up over 100F all the time, but the humidity! That's the killer). The weather has only gotten more severe as well. We are, and have been, in an Excessive Heat Warning for some time now. Today's high was potentially going to break the 100F barrier (I don't know if that has happened yet EDIT: it happened with temperatures reaching 102F in some areas) and the humidity has been between 45-80% for the week with no signs of breaking until over the weekend.

What does this mean?

High temperatures have an impact on many things, but I'll only discuss a few. One of the most apparent issues has to do with power utilities. Power outages are common during the summer months when the power grid is being taxed by large amounts of usage (what would we do without AC?). To make matters worse, severe thunderstorms common to our area have left customers without power for days at a time in some areas.

When the power goes out in your home, hopefully it is quick. But, when it's not quick your home heats up quickly and you often lose any food in the refrigerator. This isn't cheap by any means; an average family of four costs just under $250 (pdf) to feed for a week. Assuming you keep more than a week's worth of food in the refrigerator when you include condiments and what not, you could quickly be over $400.

Now think about an industrial freezer, refrigerated warehouse, or a laboratory freezer. If a refrigerator in your kitchen has at most 21 cubic feet of usable space and costs over $400 to fill, then a warehouse or industrial freezer with thousands or hundreds of thousand of cubic feet could potentially house millions of dollars in products. Even your standard refrigerator or even lab grade refrigerator (about the same size) could have tens of thousand of dollars worth of vaccines, medicine, or tissue samples. While drugs can be reproduced, samples are often priceless and are lost if not stored properly.

Ignoring the greatest downside of losing whatever it is you are storing (money) there is a safety component as well. If food spoils that can make people sick and if drugs are stored out of their proper conditions they may become ineffective; which, if you are a company, can mean even more loss of money if it gets to that point.

What can you do?

Often times your building will be on a backup generator or have a dedicated power source that possibly runs on an alternative fuel (natural gas, solar, water, etc) and this isn't a concern. Many facilities can't afford systems like these and are at the mercy of mother nature and their utility company to ensure that power is flowing to where it needs to be. The ideal solution here is to restore power as soon as possible, often that is not possible. In that case for refrigerated items, you don't want to open the container. This keeps the cool air in and will help to slow its warming. Ultimately, if the power is off for long enough the refrigerated space will warm. At this point there is nothing else you can do except to know the tolerance of what it is you are storing and how long, if at all, the goods were out of their required ranges.

Depending on the size of the area you are monitoring something small like an SM320 with probes may suit your application. Alternatively, for larger areas you could use chart recorders so that you have a paper record of the data or even the Wireless WiZARD2 System which allows you to monitor large areas from one central location. With any of these product what you get is the data. The data provides you with a record of temperatures (and humidity if you need it) that allows you to confirm any temperature excursions that occurred.

You'll notice many of these issues aren't only related to extreme heat and the lessons here can be transferred to other weather events as well. Ultimately, it comes down to knowing the temperature data and you can't do that without monitoring. Dickson provides a large line of products that can fit your applications needs and provide you and/or your company with the data it needs to stay within compliance.

In the next post I'll provide a real world example of the impact of the heat and how quickly it can take effect.