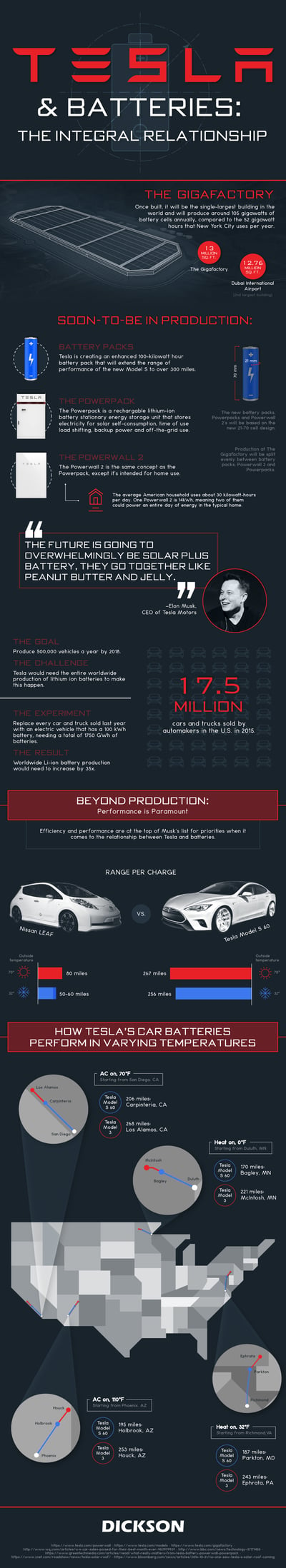

Tesla Motors, as many of us are aware, is an automaker that specializes in electric cars. Their innovations have put a charge into the industry. What they’re attempting to do next would supercharge it. They want to be able to produce 500,000 electric vehicles annually by 2018. That’s a huge increase considering they announced in 2015 that they were only producing 104,000 vehicles each year.

Tesla is also planning to create a 100-kilowatt hour (kWh) battery pack that will extend the range of their Model S electric sedan from their current range of approximately 265 miles to over 300.

How are they planning to do this? Well, for one thing, they’re going to need batteries—lots of batteries. To hit such an audacious goal, Tesla would need to increase their lithium-ion battery supply until it matched the current production of lithium-ion batteries worldwide.

Once that problem is addressed, Tesla has an even more sizable concern. Should they one day desire to replace all of the vehicles sold annually with electric cars, there were more than 17 million of them in 2015, Tesla would need access to 1,750 GWh worth of batteries. That kind of wattage would require a 3500% increase in the worldwide production of the energy sources.

That’s why Tesla is taking battery making into their own hands. In 2014 Tesla Motors broke ground on what they’re calling the Gigafactory—a lithium-ion battery factory in Nevada. Once built, the Gigafactory will become the single largest building in the world. That building will produce approximately 35 gigawatts annually. For perspective, that's the equivalent energy of approximately 36.5 million standard car batteries or more than twice the number of cars that were sold in 2015. Just keep in mind that standard car batteries aren't enough to power an electric car.

Tesla’s success, and their plans for expansion and disruption, will hinge on their relationship with the lithium-ion batteries they require. If Tesla achieves their goals, that relationship will become increasingly symbiotic. To keep up with demand and competition, both ends of the relationship will need to offer the utmost in efficiency and performance.

For consumers, though, the real question isn’t how the cars will be made, it’s how realistic of an option electric cars are for drivers across the country. Right now, Tesla’s lithium-ion batteries perform to varying levels depending on a range of factors—including temperature. Take the Model S, for example. Starting from San Diego, the Model S battery can make it 206 miles—all the way to Carpinteria, California. That’s with the AC on, and with the temperature outside around 70 degrees.

That performance can shift drastically in other parts of the country. If you were in Duluth, Minnesota, and driving with the heat on in near zero degree conditions, the Model S would only make it 170 miles. Similarly, a trip from Phoenix at 110 degrees, with the AC cranked, would only be able to make a trip 195 miles down the road to Holbrook, Arizona. The same issues, of course, exist regardless of the environmental conditions. With such varying performance, electric cars could still be difficult for many consumers to feel comfortable relying on. Those are the kinds of concerns that can impact adoption.

There is a lot of growth that will continue to consume Tesla in the years to come, but standardizing, enhancing, and innovating is going to remain key for their growth into the future. It’s going to be about reliability and consistency. Only then will they be able to truly electrify the industry.